اللولب الأحادي مقابل اللولب المزدوج: كيفية اختيار وحدة التغذية المناسبة لفقدان الوزن لحبيباتك

Release time: 2026-02-10

جدول المحتويات

Accurate and stable feeding is essential in modern material handling and processing lines, especially when working with plastic granules, chemical pellets, or food-grade materials. A وحدة تغذية لإنقاص الوزن is widely used for this purpose, offering precise gravimetric control regardless of material density changes or flow variations.

When selecting a loss-in-weight feeder for granules, one common question arises: single screw or double screw? Understanding their differences can help you avoid over-engineering or underperforming your system.

How a Loss-in-weight Feeder Works

أ وحدة تغذية لإنقاص الوزن measures material flow by continuously weighing the hopper and calculating weight loss over time. This real-time feedback allows the feeder to automatically adjust screw speed, ensuring consistent output even when material characteristics fluctuate.

Because of this closed-loop control, loss-in-weight feeders are especially suitable for applications requiring high dosing accuracy, such as compounding, extrusion, and batching processes.

Single Screw Loss-in-weight Feeder: Simple and Efficient

أ single screw loss-in-weight feeder is often the first choice for free-flowing granules. Its structure is straightforward, easy to maintain, and cost-effective for many standard applications.

Single screw designs work well when:

- Granules have uniform size and good flowability

- Feeding rates are moderate

- Space and budget efficiency are priorities

For many plastics and chemical granules, a single screw feeder provides stable feeding performance without unnecessary complexity.

Double Screw Loss-in-weight Feeder: Better Control for Challenging Materials

أ وحدة تغذية مزدوجة اللولب ذات فقدان الوزن offers enhanced feeding stability, especially for materials that tend to bridge, compact, or flow unevenly. With two intermeshing screws, material is conveyed more uniformly, reducing pulsation and improving low-rate accuracy.

Double screw feeders are better suited when:

- Granules have irregular shapes or mixed sizes

- Extremely low or highly stable feed rates are required

- Process consistency is critical over long production runs

Although the structure is more complex, the improved control often justifies the investment in demanding applications.

Making the Right Choice

Choosing between single- and double-screw designs depends less on “which is better” and more on material behavior and process requirements. Over-specifying can increase costs, while under-specifying may lead to inconsistent output and quality issues.

Manufacturers like رائع ذكي focus on matching feeder design to real-world operating conditions. By combining precise weighing technology with application-specific screw configurations, Awesome Intelligent delivers loss-in-weight feeding solutions that balance accuracy, reliability, and long-term efficiency.

Recent Transaction Cases

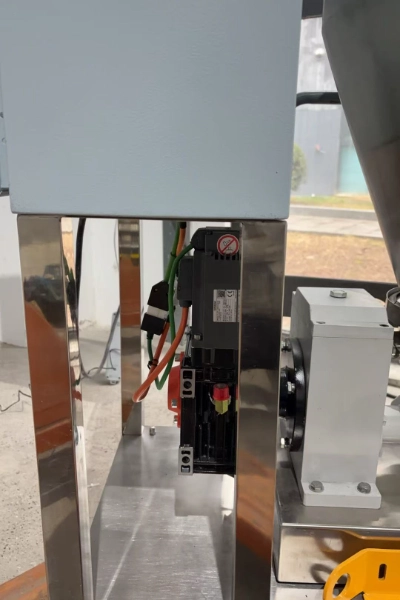

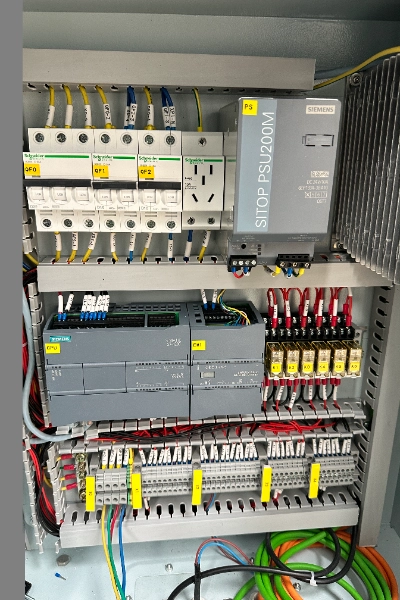

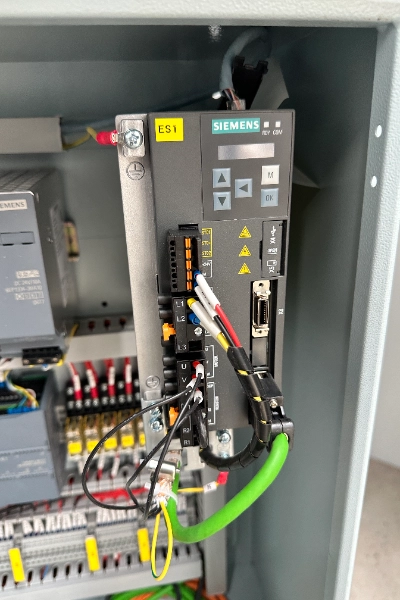

Recently, a وحدة تغذية مزدوجة اللولب ذات فقدان الوزن ordered by our customer in Argentina has been successfully completed and arranged for shipment.

This unit is designed for precise granule feeding in a continuous production line. Based on the customer’s material characteristics and required feed rate, a twin-screw configuration was selected to ensure stable conveying performance and improved low-rate accuracy. Compared with a single screw system, the double-screw structure provides more uniform material discharge, especially suitable for applications where feeding consistency is critical.

Before delivery, the equipment underwent routine performance testing, including weighing calibration, screw operation inspection, and control system verification. All functional parameters were confirmed to meet the agreed technical requirements.

The feeder has now been carefully packed and loaded for sea transportation to Argentina. We appreciate the trust from our overseas partner and look forward to supporting their production line with reliable gravimetric feeding performance.

FAQ

Q1: Can one loss-in-weight feeder handle different types of granules?

Yes, but screw design and hopper configuration may need adjustment. Some systems allow interchangeable screws for better flexibility.

Q2: Is a double screw feeder always more accurate than a single screw feeder?

Not always. For free-flowing granules, a single screw feeder can achieve excellent accuracy. Double screw designs mainly benefit difficult or low-rate feeding conditions.

Q3: How often does a loss-in-weight feeder need calibration?

In most industrial environments, periodic calibration during scheduled maintenance is sufficient, especially when using high-quality load cells and control systems.