Increased production flexibility: How can the Micro-flow Loss-In-Weight Feeder help you quickly adjust recipes and production batches?

Release time: 2025-06-16

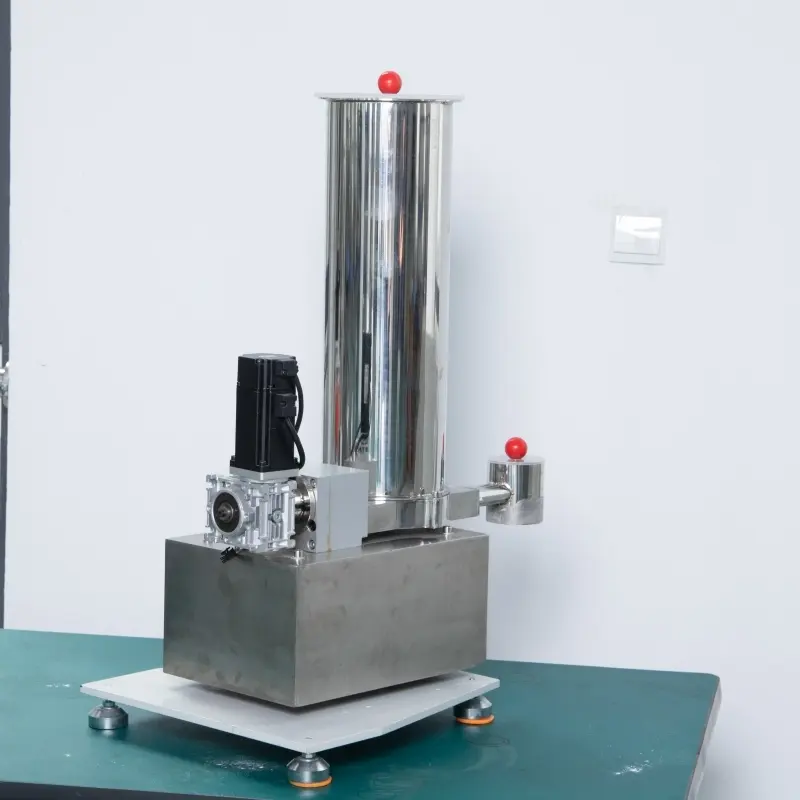

The micro-flow loss-in-weight feeder is a high-precision automatic feeding device widely used in production processes that require precise formula control, particularly in industries such as chemicals, food, and pharmaceuticals. It helps enhance production flexibility by enabling quick adjustments to formulas and production batches. Here’s how it contributes to improving production flexibility:

1. Precise Formula Control

The micro-flow loss-in-weight feeder uses a loss-in-weight feeding principle, precisely controlling the flow of materials by continuously monitoring weight changes. This allows you to deliver different components to the production line in accurate proportions according to a predetermined formula. For processes requiring the mixing of multiple ingredients in specific ratios, it ensures high consistency and stability, guaranteeing that each batch of products meets the desired specifications.

2. Quick Batch Adjustments

When production formulas or batch adjustments are required, the micro-flow loss-in-weight feeder can be reconfigured in a very short time. This flexibility enables the production line to quickly switch between different products or formulas without complex operations and long downtime. With simple interface adjustments, the feeder can rapidly adapt to the new formula requirements, increasing production efficiency and reducing product delivery time.

3. Efficient Material Usage

The micro-flow loss-in-weight feeder precisely controls the flow of each material, preventing waste or overfeeding. This precise control not only helps reduce production costs but also optimizes resource utilization, ensuring that each production run maximizes material efficiency and minimizes waste generation.

4. Enhanced Production Line Flexibility and Diversity

Since the formula can be quickly adjusted, the micro-flow loss-in-weight feeder makes the production line more flexible, meeting the demands of small-batch, multi-product production. This flexibility is especially important for industries that require frequent formula changes, enabling quick product type switching and improving overall production line utilization.

5. Real-Time Monitoring and Feedback

The intelligent micro-flow loss-in-weight feeder is typically equipped with an advanced control system that continuously monitors the flow and weight changes during the feeding process, providing real-time feedback to the control system. This allows operators to stay informed of the material status during production, ensuring precise formula adjustments and minimizing errors caused by human factors, enabling timely corrections.

6. Reduced Equipment Adjustment and Downtime

With its fast and precise adjustment capabilities, the micro-flow loss-in-weight feeder significantly reduces the time needed for equipment adjustments during production. The production line can switch formulas or batches without stopping, improving production continuity and efficiency.

7. Improved Quality Consistency

The fast and precise feeding system helps maintain product quality consistency. The raw material proportions are always the same for each production cycle, reducing fluctuations in the production process and ensuring that the final product quality remains stable.

The micro-flow loss-in-weight feeder enhances production flexibility and responsiveness by precisely controlling material delivery, quickly adjusting formulas and batches, and improving the efficiency of production lines. It not only reduces production costs and waste but also enhances product quality, enabling better adaptation to market demand changes and helping companies meet the challenges of diversified and small-batch production.